DMAIC

Overview

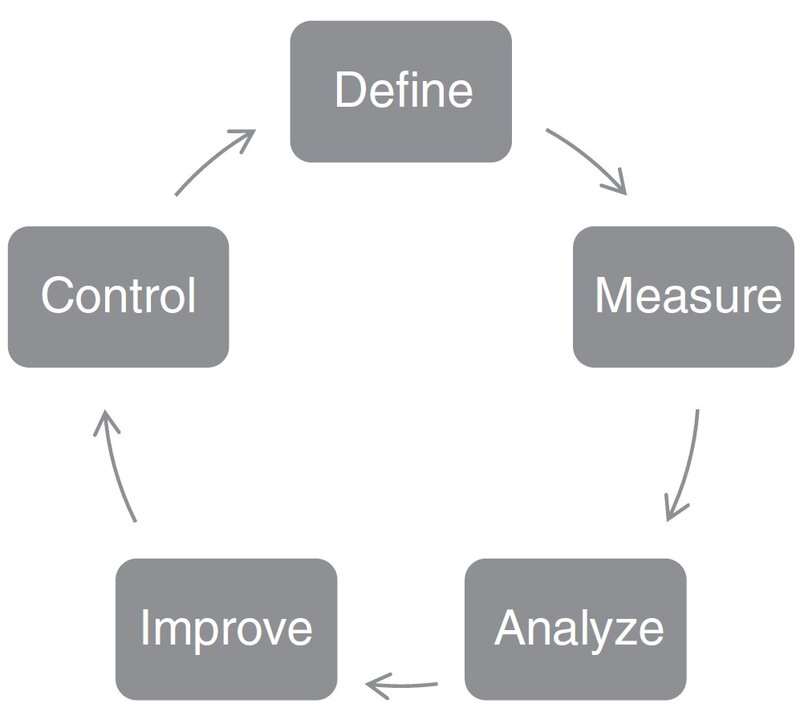

DMAIC is a structured problem-solving approach used to improve existing processes that don’t meet performance standards or customer expectations. Each project phase builds on the previous one, with the goal of implementing long-term solutions to problems. The approach is used primarily in continuous improvement, lean, and Six Sigma, but also can be implemented as a standalone quality improvement procedure or part of other process improvement initiatives.

What are the DMAIC phases?

Five phases comprise the DMAIC process:

- Define. The tools used in this phase lay the project’s foundation. The team defines the problem and project goals, and identifies customers (internal and external) and their requirements. The project charter is created. It defines the focus, scope, direction, and motivation for the improvement team, as well as includes problem and goal statements, metrics and a broad project timeline. Stakeholder analysis is performed to understand how the project may affect different areas of the organization, and a team is chosen.

A tool commonly used during this phase includes:- Voice of the customer (VOC) to understand offerings that satisfy, delight, and dissatisfy them.

- Measure. The true process is identified and documented. Process steps and corresponding inputs and outputs are identified. Measurement systems are identified or developed, and validated and improved as required. Baseline performance is established with trustworthy data.

Tools commonly used during this phase include:- Process map to record activities performed as part of the process.

- Capability analysis to assess a process’s ability to meet specifications.

- Pareto chart to analyze the frequency of problems or causes.

- Analyze. Critical inputs are identified to determine root causes of variation and poor performance (defects). These critical inputs are performance drivers.

Tools commonly used during this phase include:- Root cause analysis to uncover causes.

- Failure mode and effects analysis to identify possible product, service, and process failures.

- Multivariate charts to detect different types of variation within the process.

- Improve. Potential solutions are identified and evaluated, and the process is optimized. The critical inputs that must be controlled to maintain performance are determined. Process capability and project financials are estimated.

Tools commonly used during this phase include:- Design of experiments to solve problems from complex processes or systems in which there are many factors influencing the outcome and where it is impossible to isolate one factor or variable from the others.

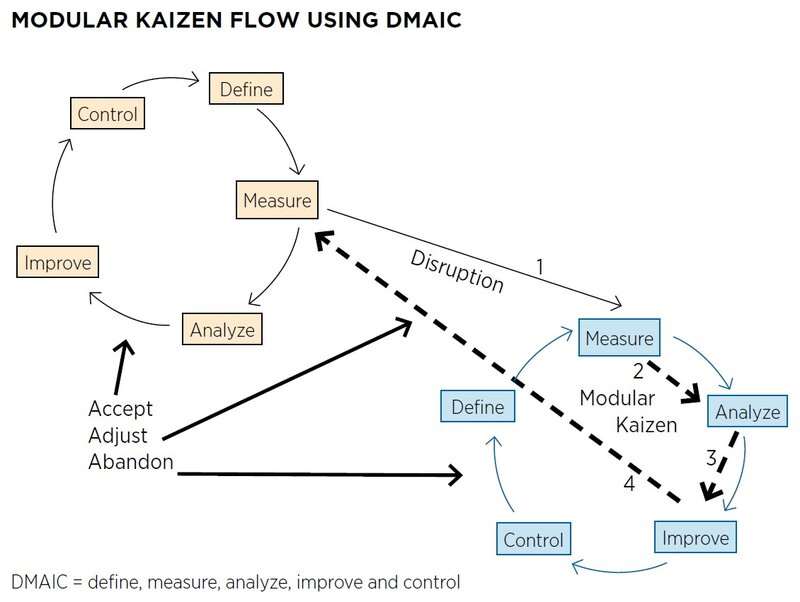

- A kaizen event to introduce rapid change by focusing on a narrow project and using the ideas and motivation of the people who perform the work.

- Control. Establish mistake-proofing, long-term measurement, and reaction plans. Develop standard operating procedures and establish process capability.

Tools commonly used during this phase include:- A control plan to document what is required to keep an improved process at its current level.

- Statistical process control to monitor process behavior.

- Five S to create a workplace suited for visual control.

- Mistake proofing (poka-yoke) to make errors impossible or immediately detectable.

When to use DMAIC

Because the DMAIC project approach guides the team through the crucial steps, it increases the chances of a successful project. DMAIC can be used for most projects—particularly if the problem is complex or high risk.

There are two approaches to implementing DMAIC:

- Teamwork. Individuals who are skilled in the tools and method, such as quality or process improvement experts, lead a team. The team members work on the project part time while also performing their regular job duties. The quality or process improvement expert might be assigned to several projects. These are long-duration projects that can take months to complete.

- Kaizen event. This is an intense progression through the DMAIC process typically done in about a week. Prep work is completed by the quality or process improvement expert, and is centered on the define and measure phases. The other phases are performed by a team. Team members have been pulled from their regular duties for the duration of the kaizen event.

In most cases, changes are piloted during the event and full-scale implementation is completed after the event. It is crucial to monitor the effect of these changes. The advantage of this approach is the ability to make rapid change.

DMAIC vs. DMADV

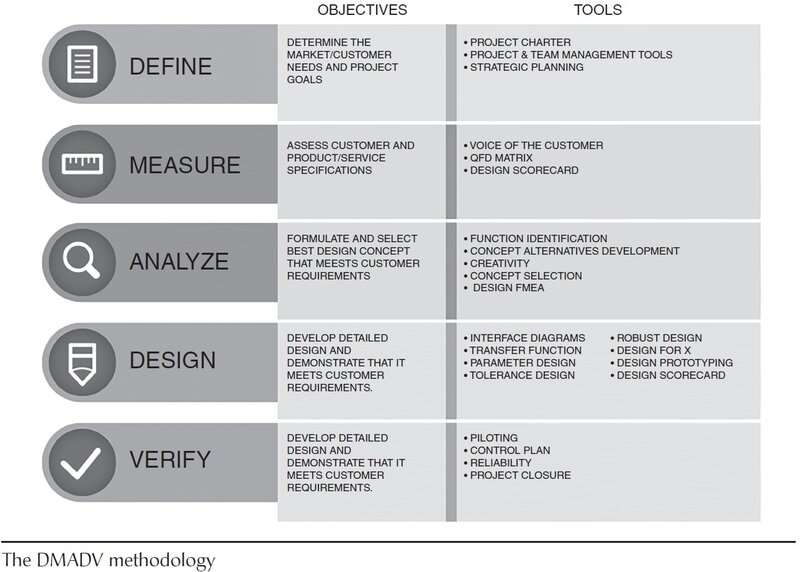

DMAIC is ideal for making incremental improvements to an existing process. Define, measure, analyze, design, and verify (DMADV), on the other hand, is used when developing new products or services, or when a process requires a complete overhaul.

five phases of DMADV are:

- Define. Determine market or customer requirements for a new product or service.

- Measure. Capture VOC and establish product or service specifications.

- Analyze. Formulate and select the best design concept to meet customer requirements.

- Design. Develop a detailed design and demonstrate that it meets requirements using tools such as pilot runs, simulations, prototypes, and models.

- Verify. Ensure the design output meets customer requirements and specifications. This can be done via testing and validating the final product or process.

Related Video

An Introduction to the PDCA Cycle, Part 2

Part 2 of this webcast series compares and connects PDCA to other methodologies, including DMAIC, lean, and ISO 9001.

Community

myASQ’s online communities provide expanded networking and learning opportunities, including blog posts, discussion threads, and library entries on topics like the fishbone diagram. Members can create new communities to generate new discussions and connections, and anyone can join online communities to reach a broader audience of quality professionals and practitioners – anytime, anywhere.

Certifications

ASQ offers 19 different certifications ranging from foundational quality to advanced quality management, including five ANSI ANAB ISO 17024 accredited programs. Earning an ASQ Certification provides you an opportunity to learn quality tools & concepts and gain a credential that can increase your earning potential and help grow your career.

Learn more about ASQ Certification

View Certification Preparation Resources (Virtual Courses, E-Learning, Question Banks, & Handbooks)

Reviewers

Mary McShane-Vaughn is principal and founder of University Training Partners in Sacramento, CA. She received a doctorate in industrial engineering and a master’s degree in statistics from the Georgia Institute of Technology in Atlanta. McShane-Vaughn is past chair of the ASQ Six Sigma Black Belt exam, author of The Certified Six Sigma Black Belt Handbook, fourth edition (Quality Press, 2023), co-author of The Certified Quality Inspector Handbook, third edition (Quality Press, 2019), and author of The Probability Handbook (Quality Press, 2016) and Lean Six Sigma Leadership (University Training Partners, 2015). She also is editor of Lean & Six Sigma Review. A senior member of ASQ and the American Statistical Association, McShane-Vaughn is an ASQ-certified Six Sigma Black Belt, quality engineer and reliability engineer.

References

Carl F. Berardinelli, “Back to Basics: To DMAIC or Not to DMAIC?” Quality Progress, November 2012, p. 72.

Grace L. Duffy, “A Systematic View,” Lean & Six Sigma Review, May 2019, pp. 8-15.

Mary McShane-Vaughn, The ASQ Certified Six Sigma Black Belt Handbook, 4th ed., Quality Press, 2022.

Scott Force, “Back to Basics: The Doctor Is In,” Quality Progress, February 2025, p. 56.

Reprints & Permissions

ASQ gladly considers requests to use its intellectual property, please see the ASQ reprint permission page for more information. For use of ASQE content or graphics, please contact us at orgmembership@asq.org to request permission.