Eight Disciplines 8D

Overview

The eight disciplines (8D) model is a problem-solving approach commonly used in the auto industry, but it also has been applied successfully in healthcare, retail, finance, government, and manufacturing. The model is used to identify, correct, and eliminate problems, making it useful in product and process improvement.

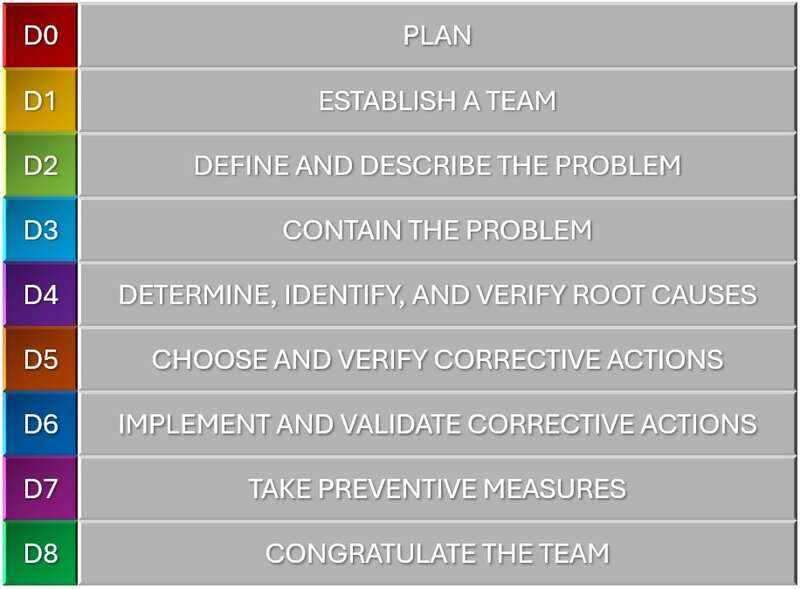

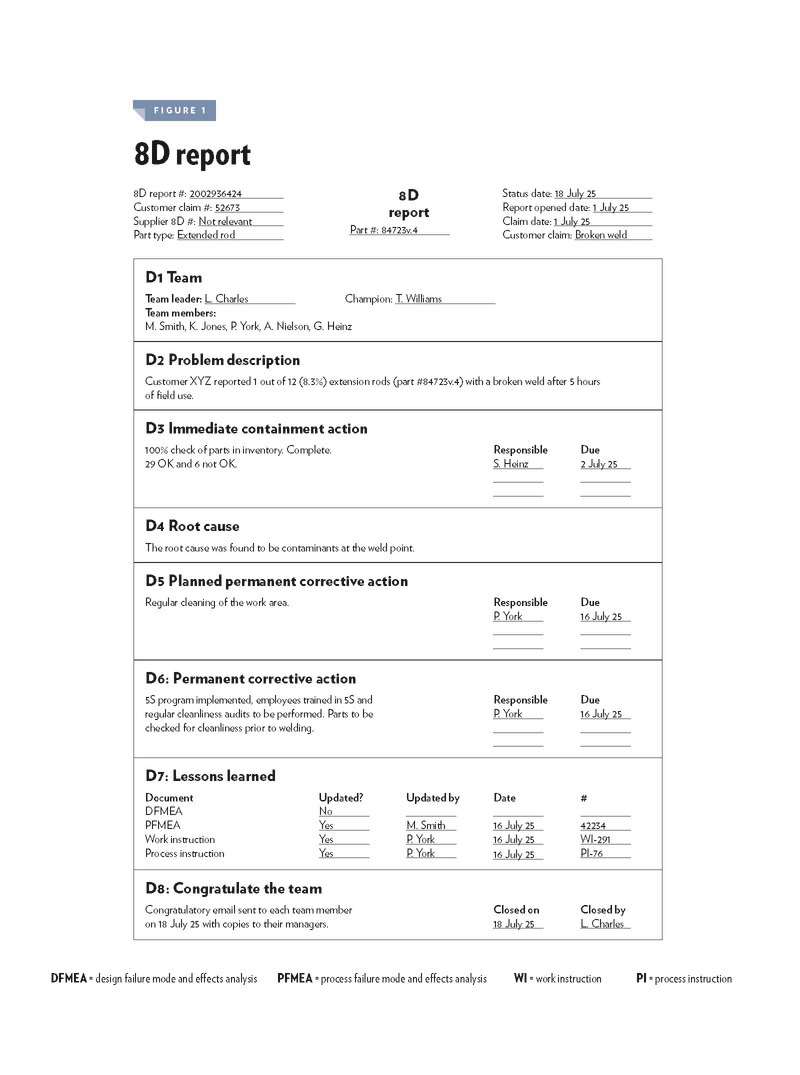

The 8D model establishes a permanent corrective action based on statistical analysis of the problem and focuses on the problem’s origin by determining its root causes. The model consists of eight steps (or disciplines) named D1 through D8. Some organizations include an initial planning stage—D0.

How to use the 8D approach

Implementing 8D involves a series of disciplined steps that build on each other to ensure a problem’s thorough resolution. Following these steps in sequence is essential because the process is designed to progress from definition and team formation through implementation and project closure. 8D’s value lies in its structured approach, organizing the problem-solving process and effectively using tools such as five whys and fishbone diagrams within this framework.

The steps are:

- D0: Plan - Plan for solving the problem and determine the prerequisites.

- D1: Establish a team - Select a team with product/process knowledge.

- D2: Define and describe the problem - Define and describe the problem—Specify the problem by identifying in quantifiable terms the who, what, where, when, why, how, and how many (5W2H) of the problem.

- D3: Develop and execute an interim containment plan - Define and implement containment actions to isolate the problem.

- D4: Determine, identify, and verify root causes - Identify all applicable causes that could explain why the problem occurred. Also identify why the problem went unnoticed when it occurred. All causes should be verified or proved, not determined by fuzzy brainstorming. Five whys and cause and effect diagrams can be used to map causes against the identified effect or problem.

- D5: Choose and verify permanent corrections - Identify the corrective action and, through preproduction programs, quantitatively confirm the selected correction will resolve the problem.

- D6: Implement and validate corrective actions - Implement the selected corrective action and verify its effectiveness.

- D7: Take preventive measures - Modify the management systems, operation systems, practices, and procedures to prevent recurrence of this as well as all similar problems.

- D8: Congratulate your team - Recognize the team’s collective efforts. The team must be thanked formally by the organization.

Download this 8D report template to use during your next problem-solving project.

Benefits and Applications

8D provides a structured approach to problem solving, ensuring all necessary steps are followed methodically. This structure aids in organizing and managing the problem-solving process effectively, and serves as a communication tool, offering a consistent framework for understanding proposed actions and their relation to the root cause.

Focusing on root causes rather than symptoms ensures effective and sustainable corrective actions, reducing defects and enhancing customer satisfaction. The method also fosters teamwork and collaboration, leveraging diverse expertise to address problems comprehensively, thus reinforcing best practices in quality culture.

8D is particularly suitable for situations in which a problem’s root cause is not apparent immediately, or when the problem affects multiple departments or functions. The method commonly is applied in scenarios involving customer complaints, product recalls, and significant deviations from quality standards.

Related Video

A3 and 8D: Alone and Together

Matthew Barsalou, author of “Back to Basics: 8D or A3,” talks about the tools’ uses, differences, and makes a request for an 8D case study.

Community

myASQ’s online communities provide expanded networking and learning opportunities, including blog posts, discussion threads, and library entries on topics like the fishbone diagram. Members can create new communities to generate new discussions and connections, and anyone can join online communities to reach a broader audience of quality professionals and practitioners – anytime, anywhere.

Certifications

ASQ offers 19 different certifications ranging from foundational quality to advanced quality management, including five ANSI ANAB ISO 17024 accredited programs. Earning an ASQ Certification provides you an opportunity to learn quality tools & concepts and gain a credential that can increase your earning potential and help grow your career.

Learn more about ASQ Certification

View Certification Preparation Resources (Virtual Courses, E-Learning, Question Banks, & Handbooks)

Reviewers

Matthew Barsalou works in the auto industry in Germany. He has a master’s degree in business administration and engineering from Wilhelm Büchner Hochschule in Darmstadt, Germany, and a master’s degree in liberal studies from Fort Hays State University in Hays, KS. Barsalou is an academician in the International Academy for Quality, an ASQ fellow and was the 2021 chair of ASQ’s Statistics Division. He is a certified lean Six Sigma Master Black Belt and an ASQ-certified Six Sigma Black Belt, manager of quality/organizational excellence, quality technician and quality engineer.

References

Arp Jr., Don, Gary G. Jing, Katie Labedz, Stephanie Parker and W. Frazier Pruitt, “Tool Talk,” Quality Progress, August 2024, pp. 12-25.

Barsalou, Matthew, “Back to Basics: 8D or A3?” Quality Progress, January 2023, p. 56.

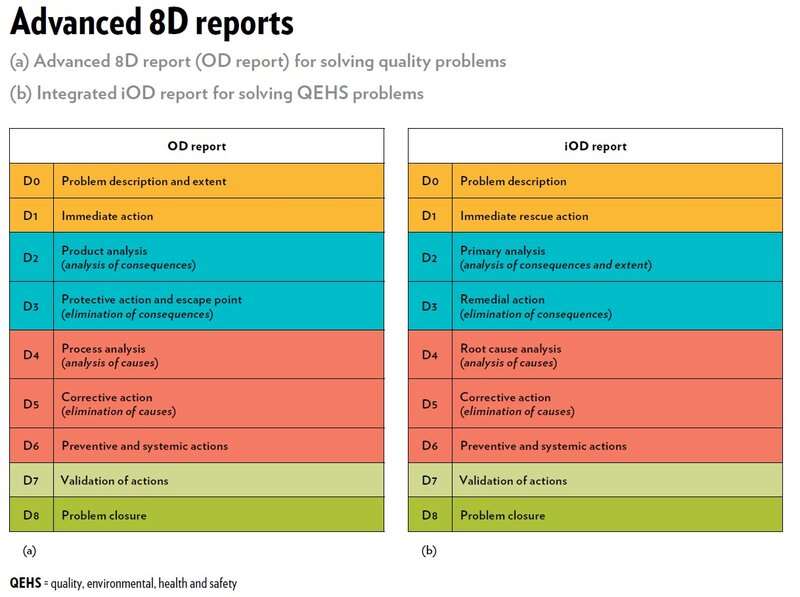

Barsalou, Matthew, “It’s All in the Approach,” Quality Progress, June 2025, pp. 20-25.

Durej, Ondrej, “A New Slant,” Quality Progress, October 2024, pp. 34-45.

Pruitt, W. Frazier, “Back to Basics: A Disciplined Approach,” Quality Progress, May 2019, p. 64.

Reprints & Permissions

ASQ gladly considers requests to use its intellectual property, please see the ASQ reprint permission page for more information. For use of ASQE content or graphics, please contact us at orgmembership@asq.org to request permission.